About Us

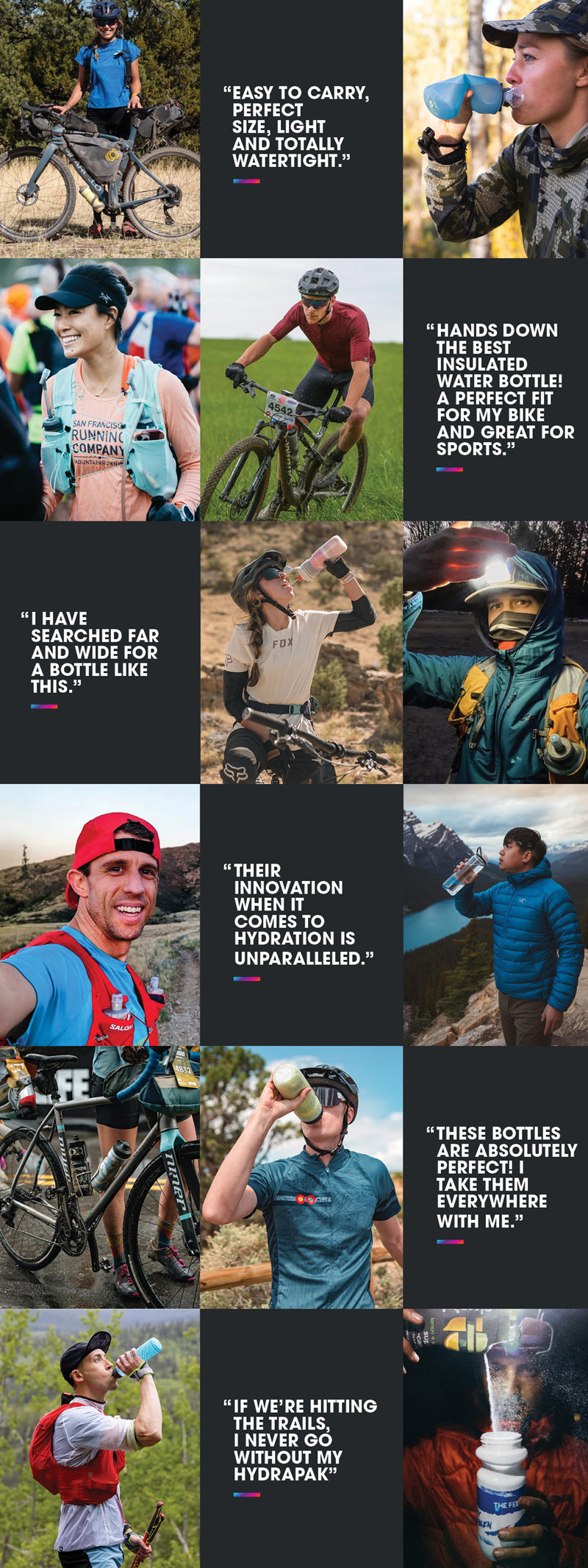

We are hydration experts.

We’ve been designing and producing performance hydration systems for over 20 years, and our mission is to help athletes reach their peak performance. By offering better ways to hydrate, HydraPak has pioneered new product categories and become a trusted partner for athletes and brand partners worldwide.

History

HydraPak was founded in 2001 in Northern California. Over the past two decades, HydraPak has become the number one original equipment manufacturer of reservoirs and soft flasks in the world. Its owned brands, Polar Bottle® bicycle squeeze water bottles and Bottle Bright® all-natural cleaning tablets, are leaders in their categories.

History

HydraPak was founded in 2001 in Northern California. Over the past two decades, HydraPak has become the number one original equipment manufacturer of reservoirs and soft flasks in the world. Its owned brands, Polar Bottle® bicycle squeeze water bottles and Bottle Bright® all-natural cleaning tablets, are leaders in their categories.

BRAND PROMISES

We are the hydration experts, and it is our focus on providing the right solution for the right customer that sets us apart.

- Innovate: We relentlessly innovate for a range of unique challenges to ensure that each athlete gets exactly what they need to perform at their peak.

- Perform: Athletes depend upon our products in the harshest of environments. Our products must perform and be reliable - everytime.

- Educate: As performance hydration experts, it is our job to lead athletes to the best hydration solution.

- Support: We stand behind our products with category-best warranty service and we solve every product defect.

BRAND PROMISES

We are the hydration experts, and it is our focus on providing the right solution for the right customer that sets us apart.

- Innovate: We relentlessly innovate for a range of unique challenges to ensure that each athlete gets exactly what they need to perform at their peak.

- Perform: Athletes depend upon our products in the harshest of environments. Our products must perform and be reliable - everytime.

- Educate: As performance hydration experts, it is our job to lead athletes to the best hydration solution.

- Support: We stand behind our products with category-best warranty service and we solve every product defect.

CORE VALUES

We chose the acronym A.T.H.L.E.T.E. because we are laser focused on supporting the hydration needs of athletes. At HydraPak, we are:

- Advocates

- Team Players

- Honest

- Long View Thinkers

- Entrepreneurs & Innovators

- Tolerant & Respectful:

- Eco Conscious

CORE VALUES

We chose the acronym A.T.H.L.E.T.E. because we are laser focused on supporting the hydration needs of athletes. At HydraPak, we are:

- Advocates

- Team Players

- Honest

- Long View Thinkers

- Entrepreneurs & Innovators

- Tolerant & Respectful:

- Eco Conscious